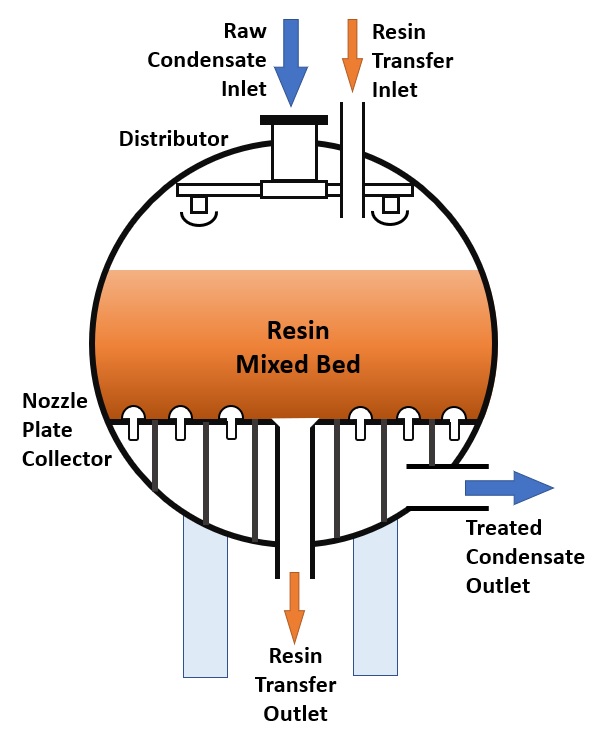

Condensate polishers are resin-based ion exchange systems that are commonly used in power plant condensate systems to remove dissolved contaminants (chlorides and silica) and suspended contaminants (iron or copper oxide particulates).

Condensate polishers are used to maintain a proper quality of water by removing impurities from return condensate. The decision to polish return condensate for re use is purely economical. The condensate can be returned to an ultra-pure state by simple polishing rather than using fresh make-up process water.

Condensate polishing typically involves Ion Exchange technology for the removal of trace dissolved minerals and suspended matter. During the process of steam generation in power plants, the steam cools and condensate forms. The condensate is collected and then used as boiler feed water.